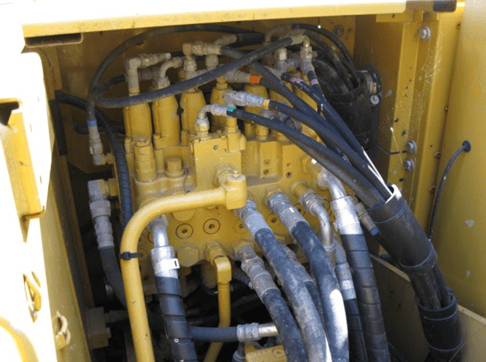

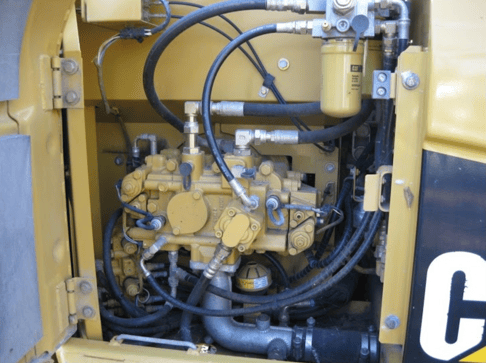

Hydraulic hoses are the circulatory system of your hydraulic machine. When they fail, the entire machine can compromised. In this Shop Talk Blog post, we are going to talk about some of the most common causes of hydraulic hose failure on heavy equipment, and what can be done to prevent those failures.

Heat Aging

When hydraulic hoses are exposed to high temperatures for extended periods of time, it can result in heat aging. The inner tube of the hydraulic hose will begin to harden as plasticizers in the elastomer break down due to the extreme heat. As these plasticizers break down, the inner tube of the hose will begin to harden and then crack. One way to tell if a hose is suffering from heat aging is to check its behavior after it is removed: it will retain the same shape after removal and, if bent, may make a crackling sound. This type of failure can be prevented by routing hoses away from high temperature areas or, if that is not possible, installing a heat shield or heat guard over the hose to insulate it from the extreme temperatures.

Abrasion

Another major cause of hose failure is abrasion. This occurs when the hose is rubbing against another hose or another surface. This repeated contact causes the outer layers of the hose -- the hose cover -- to slowly wear away, weakening the hose and eventually resulting in a leak. Hoses do move when pressurized, and vibrating equipment can also contribute to abrasion. To prevent abrasive failure, you can reroute them from problematic areas or place protective shield and covers on your hoses.

Site Damage

Site damage occurs when the hoses are damaged by things in the environment in which they work. This is especially common with construction equipment, where there are things like rebar of chunks of concrete that can result in a nick, a tear, or a cut to a hydraulic hose. In more extreme cases, hoses can be severed or crushed. Hoses exposed to the elements should have a protective shield or cover over them to minimize potential damage.

Hydraulic Contamination

You might not think of hydraulic contamination as being a source of hose damage, but it can pose a very real threat. If you imagine a tiny sliver of sharp metal (too small for the filters to catch) passing through the hose at high velocity and temperature, it becomes easy to also imagine the damage that can be done to the inner tube. A cut or slice in the inner tube of the hydraulic hose only leads to more problems including leaks.

Wear and Tear

Hydraulic hoses are not meant to last forever. Many people don’t realize that the service life of a hydraulic hose is based on cycles rather than hours in service. This is because the pressurization and depressurization cycles have the most impact on hose life. Keep an eye on your hydraulic hoses and check them for signs of impending failure. When a hose begins to leak or looks compromised, replace it according to manufacturer recommendations.

Conclusion

Take good care of the hydraulic hoses on your machine, rerouting them away from areas that can cause damage like heat aging or abrasion and using protective covers and insulating shields as needed. Don’t let the circulatory system on your machine fail at the wrong time! It can lead to something wrong with your final drive.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.