Final drive motors are hydraulic motors with a speed reducing, torque multiplying planetary gear set. In this Shop Talk Blog post, we’ll talk about planetary gear sets, the parts that make them up, and how they work. We'll also look at some examples taken from actual final drives and then discuss how to maintain your gearbox.

Here are a few other blog posts you might enjoy ...

- Final Drive Motors and Gears

- 3 Things You Should Know About Gear Oil for Final Drives

- How to Troubleshoot an Overheating Gear Box

Low Speed, High Torque Motors

Most of the hydraulic motors used for propel motors are low-speed, high-torque (LSHT) motors. Speed and torque are related by power:

Power = Speed x Torque

That means if we want to increase torque for a given horsepower, we need to reduce speed:

Torque = Power / Speed

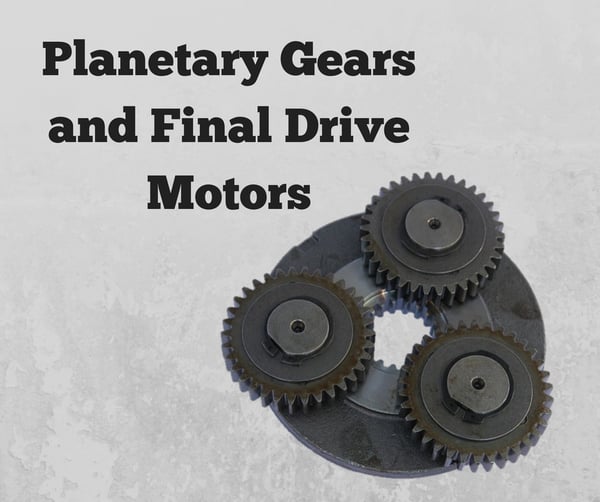

Hence the term "low-speed, high-torque." One way of reducing speed involves the use of planetary gears. They provide speed reduction which results in torque multiplication. And they do this all in a compact package when compared to gear and pinion speed reducers, and that means they have excellent torque density. Below you can see a planetary gear system from a final drive motor.

Planetary Gear Systems

In a final drive gear hub, you will usually have two sets of three planetary gears that rotate about a sun gear. They also mesh with a stationary ring gear. The upper set of planetary gears are held together by a carrier, as shown in the image above. As you can see, all three gears are arranged an equal distance from each other. At the center is a place for sun gear to mesh and provide input to the system.

How Final Drive Planetary Gears Work

Let's take a simplified look at how the planetary gears in a final drive work. Input power causes the sun gear to rotate at high speed. The planets mesh with both the sun gear and the ring gear. They orbit the sun gear while rolling around the ring gear. The result is low speed, high torque output rotation.

Maintaining the Planetary Gearbox

On a final drive motor, the planetary gearbox requires gear oil, also known as gear lube. It is essential to check the gear oil levels about every 100 hours and change the gear oil once a year. If you don’t change out your gear oil, you’ll end up with a thick sludge that will lead to excessive wear of your planetary gear system. Here at Texas Final Drive, we refer to that as “pudding.”

Another key aspect of maintaining your planetary gearbox is fixing any leaking seals right away. If a seal is degraded enough to allow oil to leak out, then that means dirt and dust can make their way in. You don’t want to have your gears look like the gritty mess shown below.

Conclusion

Your planetary gearbox is a key component of your final drive. If it fails, you won’t be able to generate the torque you need to keep your machine moving. Remember to check and change the gear oil and don’t ignore leaks. And don't forget that pudding and grit are not what you need in your gearbox!

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.