Your hydraulic pump is the heart of your machine, pumping fluid through your hydraulic system. Pump failures mean downtime and expensive repairs, but the sooner you recognize pump problems developing the easier it is to fix. In this Shop Talk blog post, we are going to discuss, we are going to discuss the most common signs and causes of hydraulic pump failure.

Signs of Imminent Pump Failure

There are certain signs that often accompany hydraulic pump failure, including …

- Knocking and banging sounds or unusual vibration

- Sudden drops in pressure

- Weak final drive motor

- Leaking hydraulic fluid

- Pump seals that repeatedly fail

- Erratic or weak cylinder operation

- Abnormally high temperatures while the pump is running

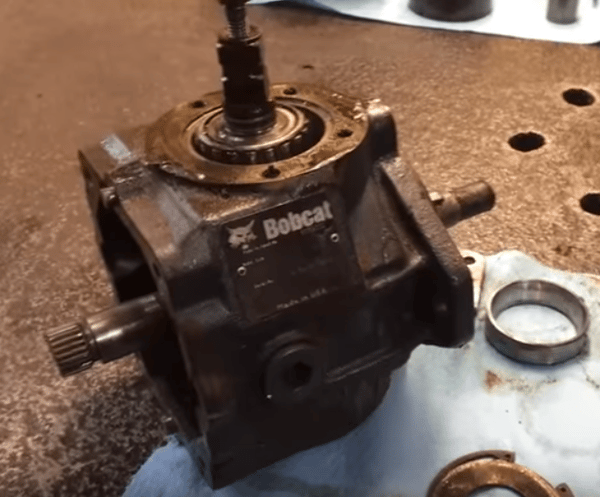

If you notice any of these symptoms, keep in mind that it doesn’t necessarily mean that the pump is going out -- but it means something in your hydraulic system is about to! Check out this video below for an example of what can happen to a Bobcat pump.

Typical Causes of Pump Failure

There are various issues that can lead to pump failure, and the following are the most common causes: air contamination, bent or misaligned rod, general contamination, or normal wear and tear.

Air Contamination

If you get air in your hydraulic system, the pump will start making banging or knocking sounds, cavitation will begin to develop, your pump will start to overheat, and the interior parts of your pump will begin to suffer some pretty bad damage. You’ll see a loss in performance and eventually, it can lead to catastrophic failure. Air usually makes it way in through faulty shaft seals or inlet joints that are leaking.

Bent or Misaligned Rod

A bent or misaligned rod can cause problems, too. If you notice that your seals are repeatedly failing, this could be the cause. And keep in mind that a seal that leaks also allows contamination to get inside.

General Contamination

Contamination is one of the major causes of pump failure. Just like we see with final drive motors, a contaminated pump can be destroyed if contamination is allowed to continue unchecked. Preventing contamination is a fairly straightforward process that can save you hundreds, if not thousands, in repair and replacement costs.

Normal Wear and Tear

Sadly, no pump will last forever because they suffer wear and tear from regular use. Bearings and seals will eventually need to be replaced, and if those replacements are put off then your pump may suffer even worse damage. If you suspect your hydraulic pump needs a tune up, then don’t hesitate to see after it -- it will extend the life of your pump and increase your machine’s overall productivity.

Conclusion

Pumps are vital to the operation of your equipment, and when they fail the costs can quickly skyrocket. That’s why it important not to ignore the signs of impending pump failure, such as knocking or banging noises, drops in pressure, a weak final drive, leaky seals, erratic cylinder operation, or high temperatures.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.