The effects of cavitation are usually pretty easy to identify -- it causes a metal surface to have a pitted, crater-like appearance. What happens when cavitation takes place, and how it actually causes damage to normally resistant metals, isn’t quite as well known. In this Shop Talk Blog post, we’ll be talking about what causes cavitation and why it can result in so much damage.

Here are a few other posts from our Shop Talk Blog series ...

- 6 Types of Hydraulic Fluid Contamination

- Bobcat 325 Rotator Group Damage

- #1 Caused of Final Drive Failure

What is Cavitation

Cavitation damage is a type of erosion that can affect hydraulic components. In hydraulic motors and pumps, it often affects the valve plates.

In a nutshell, cavitation results when hydraulic fluid forms vapor bubbles as a certain pressure is reached and then bubbles collapse as pressure drops -- and as the bubbles burst, they damage nearby metal because of the extreme pressures, forces, and stresses that are involved.

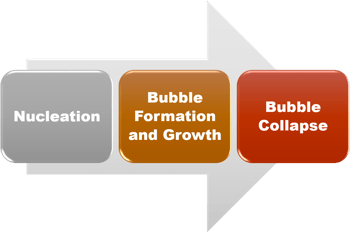

There are three basic stages to cavitation: nucleation, bubble formation and growth, and bubble collapse. Note that damage doesn’t occur until the third stage -- collapse -- is reached.

Nucleation

Nucleation is actually a phase change, from liquid to vapor, that occurs due to a pressure drop. Now, in order to this phase change to occur, nucleation sites must be present. What is a nucleation site, you ask? Nucleation sites promote the occurrence of the phase changes, and include …

- Contaminants (include solids and gases)

- Air bubbles in the hydraulic fluid

- Turbulence in the fluid flow

- Sharp edges on surfaces

Note that the more contaminated the hydraulic fluid, the more likely you will have nucleation sites and nucleation.

Bubble Formation and Growth

The critical pressure of most hydraulic systems is close to the equilibrium vapor pressure at the operating temperature of the hydraulic fluid, which means it is very easy for the fluid to become a vapor. As liquid flashes into vapor, the result is bubbles that are filled with a mixture of air and oil vapor. The result is a wide assortment of bubbles that begin to expand in size.

The bubbles are carried away from the nucleation site by the flow of hydraulic fluid. They travel to a region of higher pressure. Then, as the bubble expands, the pressure immediately around the bubble begins to increase. As that pressure goes up, it begins to deform the bubble into a kidney shape.

Bubble Collapse

Bubble collapse is when the damage occurs. As the pressure external to the bubble deforms it, a tiny, tiny droplet called a microjet forms inside the bubble. The bubble collapses, or implodes, as the microjet hits the wall of the bubble at terrific speed. A shockwave is released as the bubble collapses in on itself, its walls colliding against each other.

Any nearby solid surfaces get hit with pulse loads from multiple implosions as the nearby bubbles rapidly collapse. The result is a repeated stress that, over time, leads to fatigue failure of the surface of the material.

By hydro-tg hydraulique [GFDL or CC-BY-SA-3.0], via Wikimedia Commons

As the cavitation process continues over time, fragments start to come loose from the nearby material. This is what gives it a pitted, crater-like appearance. The actual rate of erosion, or how fast damage takes place, is related to the strength of the material and its geometry.

Conclusion

Cavitation is, to some degree, inevitable. However, one of the secrets to minimizing cavitation lies in keeping your hydraulic fluid as clean as possible, including free from air bubbles. The cleaner your hydraulic fluid, the less likely you will be to have nucleation sites that lead to cavitation.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.