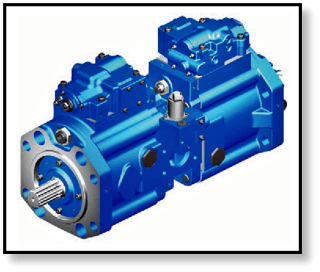

How much do you know about hydraulic pumps? In this Shop Talk Blog post, you will learn about the debate on whether pumps generate pressure, understand the meaning of a pump's pressure rating, recognize different types of pump efficiency, and learn the difference between head and pressure.

Do hydraulic pumps generate pressure?

It's time for some engineering talk. Here's an interesting debate between engineers: do pumps generate pressure or not? Pumps produce fluid flow that results in pressure only when that flow meets resistance. If a pump is not hooked up to a system, the pressure at the pump outlet will be zero because there is nothing to resist the flow of fluid. This lack of pressure leads many engineers to state that pumps do not generate pressure.

However, not everyone agrees with this. There are some excellent arguments for pressure as opposed to fluid flow. When modeling pumps in a system, modeling pumps as a pressure source instead of as a source of flow have been found to be far more accurate.

What does the pressure rating of a pump mean?

You've probably noticed that hydraulic pumps have pressure ratings. The pressure rating refers to how much pressure a pump can handle before it begins to leak or experience damage. Another way to look at it is that the pressure rating represents how much pressure the pump can maintain a flow against. Therefore, you need to make sure the pressure rating of your pump is below the system pressure it will be working with.

What is the difference between volumetric, mechanical, and overall efficiency?

There are at least three different types of efficiency measures for hydraulic pumps: volumetric, mechanical, and overall. The volumetric efficiency is the actual flow at a given pressure divided by the theoretical flow. Actual flow is measured using flow meter, while theoretical flow is determined by multiplying the driven speed of the pump in rpm by the displacement per revolution of the pump. Volumetric efficiency is good way to get a feel for the performance of a pump and can be used to estimate pump performance in the field.

Mechanical efficiency, also known as hydraulic efficiency, is the theoretical torque required to drive the pump divided by the actual torque needed to drive the pump. Overall efficiency is the product of volumetric efficiency and mechanical efficiency. Most axial piston motors will have an overall efficiency of around 91%.

What's the difference between head and pressure?

What's the difference between head and pressure?

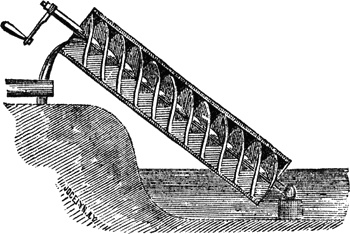

Some confusion arises when pumps are rated in terms of head instead of pressure. There's a very simple formula for converting between head and pressure: pressure (psi) = head (ft)/2.31 or head (ft) = 2.31 x pressure (psi). The use of head originated with the work of the Greek mathematician and scientist Archimedes and his innovative screw pump design.

Conclusion

Hydraulic pumps are key to the functionality of your heavy and compact equipment, but sometimes the terminology can get confusing. There's no shame in a quick Google search to double-check something you may be unsure about. Are there any concepts or terms that you'd like to learn more about? Why not leave us a comment so we can try to address it in a later blog post?

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.