You probably have memories of childhood that involve either riding a Ferris wheel or wanting to ride one. They seem almost magical as the massive wheel full of passengers turns slowly, lifting everyone up into the sky for a few moments. You may not be aware of it, but many Ferris wheels and tracked machines have something in common: hydraulic final drive motors.

Modern Ferris Wheel Design

Most people think there is a motor of some type in the center of the wheel that makes it turn, and while that might have been true of older designs there is a more modern approach. Many of the largest wheels use hydraulic motors with planetary gear speed reducers to generate torque at the circumference of the wheel rather than at the center. The motors and gearboxes rotate large rubber tires. These high-friction rubber tires press against the circumference of the wheel and, in turn (pun intended) cause it to rotate.

Khamtran [CC BY-SA 3.0 or GFDL], from Wikimedia Commons

An excellent example of this type of design would be the observation wheels created by the Great Wheel Corporation located in Dubai, Saudi Arabia. They are responsible for mega-wheels such as the London Eye and the design behind the Great Wheel of Beijing (which, sadly, was not completed due to financial issues). Another example of an observation wheel designed along these lines is world’s most massive one in Dubai, known as Ain Dubai. The Dubai wheel is 668 feet tall -- a little over ⅔ of the height of the Empire State building. The wheel will carry 1,400 passengers, and we can only imagine the type of torque necessary to get that wheel turning and then stop it once the ride is complete.

Paasikivi [CC BY-SA 4.0], from Wikimedia Commons

Beijing Great Wheel

The Beijing Great Wheel was going to require a massive amount of torque -- on the order of 66 million ft-lbs at a speed of 3 revolutions/hour and a drive force of over 200,000 lbs. That torque and drive force were to be provided, as mentioned earlier, by hydraulic motors and planetary gearboxes. And the companies that are providing that type of equipment for hydraulics and controls are well-known, including Bosch Rexroth and Boxtel.

According to an article on Hydraulics & Pneumatics, the Beijing Great Wheel would have had four drive units. Each drive unit would contain two hydraulic drive modules, and one of them serves as a backup unit in case the other fails. For each drive module, there would be a hydraulic power unit (HPU) that feeds four hydraulic motors that have planetary gear speed reducers. That means a total of 32 hydraulic motors power for powering the towering wheel.

Why Hydraulics Are Used for Modern Observation Wheels

There are several reasons why hydraulics were chosen for these massive observation wheels. Not only can hydraulics generate a tremendous amount of torque, but they can provide that torque with a compact design that results in very high power density. Hydraulic systems can also achieve very smooth acceleration and deceleration, which can be pretty important if you are over 400 feet up in the air. Hydraulic designs also generate low heat and considered easier to maintain than some of the other options out there.

Ferris Wheels and Tracked Machines

Most Ferris wheels and tracked machines both LSHT motors and speed-reducing planetary gear sets in common. Both of them need massive amount of torques, smooth operation, high power density, and relatively easy maintenance. Its interesting that hydraulic motors can be critical to both work and play!

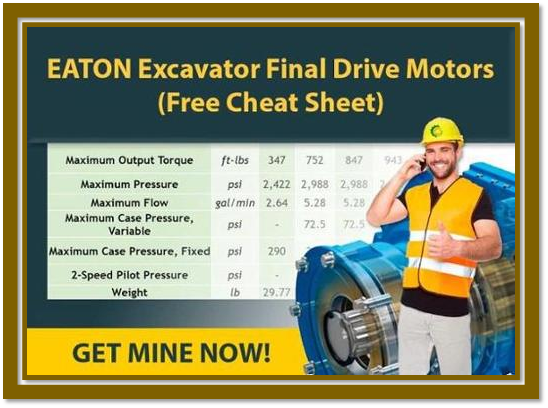

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.