If your tracks don't move that easily anymore or your machine starts to steer to one side, it could be that your gear teeth on your drive shaft have been worn down; this is what is known as a "stripped drive shaft". One of the most common problems found on Kubota and Hy-Dash final drives involves a stripped drive shaft. In this Shop Talk Blog post, you’ll learn how to identify a few symptoms of a stripped drive shaft, what can be done about it, and how to prevent it from happening to your final drive.

Symptoms of a Stripped Shaft

Symptoms of a stripped drive shaft on a Kubota excavator can include any of the following:

- Excavator steers to one side

- One side of the tracks refuse to move

- Final drive motor seems to skip

- Final drive motor seems weak or experiences a loss in power

What Happens When a Drive Shaft is Stripped

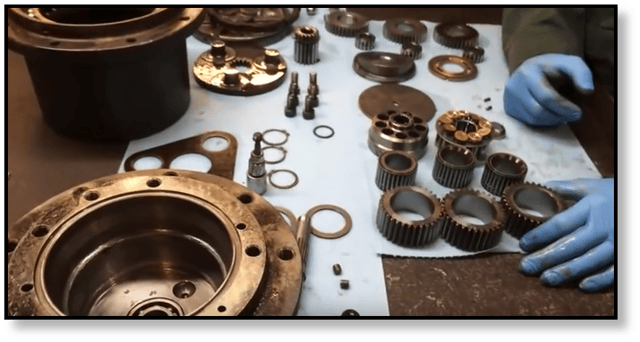

When the gear teeth on the lower drive shaft of your Hy-Dash or Kubota final drive are stripped or severely worn, the drive shaft can no longer engage the coupling. That means that no matter how much power you send to the final drive, it won’t be able to make a good enough connection to move the tracks consistently. The picture below shows an extreme case where the teeth are almost completely worn away. Remember that the metal from those teeth have to go somewhere. Even if they are eventually filtered out, they can do damage to the inside of your travel motor or final drive.

The image below shows a lower drive shaft in good condition and one in poor condition (although not quite as bad as the previous example). You’ll notice the severe wear experienced by the teeth on the worn drive shaft. Anytime gear teeth look pointed, something needs to be replaced. That goes for drive shafts, planetary gears, and even the sprocket that drives the tracks. Gear teeth in good condition should have a thick, flat surface on the tips, like the shaft shown on the right. This allows for effective engagement with the coupler.

Repairs

The only way to repair a stripped coupling and shaft -- or anything with gear teeth that are stripped or worn down -- is replacement of the worn the parts. Replacement shafts and couplers are not difficult to track down for Kubota machines. Fortunately, this type of damage does not require an expensive overhaul of the final drive unless there is damage from contamination resulting from the wear on the gear teeth.

Preventing a Stripped Shaft

This type of extreme wear on the main shaft and coupling is typically caused by going back and forth too rapidly on the toggles/joysticks. It very similar to going into drive on your vehicle and then immediately putting it into reverse -- all while skipping neutral. You know that would be rough on your car; imagine what it can do to your final drive motor!

Conclusion

A stripped shaft can be prevented by not making a habit of switching between forward and reverse quickly. If you do notice that your Kubota excavator is showing some symptoms associated with a stripped shaft, you need to get it checked out in a timely manner. The longer you let it go, the more you risk contamination damage -- and a very expensive repair.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.