The John Deere 35C and 35D are two popular excavators from the Deere line of mini-excavators. In this Shop Talk Blog post, we’ll talk about some of the features that make them stand out from other mini-excavators and discuss some of the applications they are well suited for.

John Deere 35C/35D Features

With their zero-turn radius (which is why they often have the abbreviation ZTS after their name), you don’t have to worry about the Deere 35C or 35D bumping into anything while rotating. This is true even when working in tight quarters. They both have 360° rotation and an independent swing boom, which allows you quite a bit of freedom when getting in position to do your work. The John Deere 35C/35D are also well adapted to residential applications because of their compact size and versatility. The 35D only needs about 69 in. of room between objects to fit between them. This also makes it easy to transport them to the work site.

Both of these machines are also compatible with a wide variety of attachments and equipped with a standard quick coupler and auxiliary hydraulics. These machines also have good drawbar force, which comes in handy for backfilling. Both of them also come with two-speed, axial piston hydraulic propel motors.

By Ildar Sagdejev (Specious) [GFDL or CC BY-SA 4.0], from Wikimedia Commons

Available Attachments

There are a ton of attachments available for these compact excavators. Here are some examples: augers, hydraulic breakers, rebar cutters, rippers, thumbs, trenchers, saw heads, forks, articulating buckets, rakes, mowers, tilting buckets. Switching between attachments is easy because of the standard quick coupler.

Typical Tasks

Given the variety of attachments available, there are a number of different tasks that the John Deere 35C and 35D can perform, such as ...

- Prepping grounds for landscaping

- Removing debris from construction sites

- Moving trees and rocks

- Lifting pallets

- Tearing down fences and poles

- Repairing sewer lines

- Loading crawlers or pickup trucks with sand, dirt, or gravel

- Removing stumps

- Digging up sensitive materials like conduit

- Installing fence posts

- Digging and backfilling trenches

- Small-scale demolition and cleanup

- Grading dirt

- Breaking up concrete

Of course, these would require the appropriate attachments.

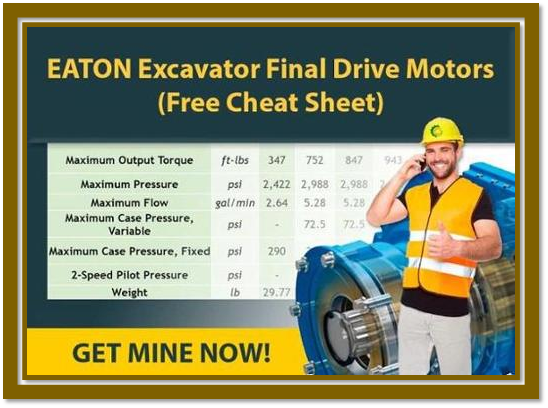

A Note on the Final Drives

As you know, final drives are our thing. That said, GL-5, SAE 80W90 Gear Oil is recommended for the planetary side of the hydraulic motors for these machines. The 35C will need about 0.5 quart, and the 35D will need about 0.7 quart. If you want those final drives to last, check and change the gear oil on a regular basis. Pay attention if any leaks start, and don’t ignore any problems that develop.

Conclusion

The John Deere 35C and 35D are versatile, sturdy, and compact excavators that can perform a variety of different tasks. With the right attachments, you can do everything from dig trenches near conduit to demolish a small house. What they may lack in power compared to full-size excavators they more than make up for in their maneuverability and zero-turn radius.

Here are a few other related blog posts that you might find helpful ...

- 4 Bad Habits That Mini-Excavator Owners and Operators Need to Quit

- Anatomy of a Good Maintenance Plan for CTLs and Mini-Excavators

- Maintaining the Final Drive on Your Excavator

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.