A sudden hydraulic line blowout is more than just an inconvenience—it can shut down your jobsite, delay your project, and cost you in lost time and fluid cleanup. Whether you’re an independent contractor relying on a single machine or a rental business trying to avoid customer complaints, understanding how and why blowouts occur is essential.

This Shop Talk Blog post will not only help you recognize the risks, but also empower you to spot the warning signs early and take simple steps to prevent disaster before it strikes. Your proactive role in this process is crucial.

Here are a few more blog posts you might find helpful:

- Hydraulic Hoses and Final Drives

- 5 Things to Avoid Doing with Hydraulic Hoses

- Exploring Hydraulic Connectors

What Is a Hydraulic Line Blowout?

A hydraulic line blowout occurs when a hose or fitting fails suddenly and catastrophically, causing pressurized hydraulic fluid to spray or gush out. Unlike slow leaks that develop over time, a blowout happens in an instant, and the results can be dramatic. You might see a sudden loss of machine function, hear a loud pop or hiss, or witness a high-pressure stream of fluid spraying from the hose.

Common Causes of Hydraulic Hose Failure

Here are the most common causes of hose failure you’ll want to watch for:

Abrasion: Hoses that rub against metal parts, other hoses, or the machine's frame can develop weak spots and eventually rupture. Without proper routing and clamps, even a new hose can wear down quickly.

Excessive Pressure or Pressure Spikes: Hydraulic systems operate under intense pressure, and if that pressure exceeds a hose’s rated capacity—especially during startup or operation—failure is almost inevitable.

Aging and Dry Rot: Hoses degrade over time. Exposure to sunlight, high temperatures, and chemical contaminants can cause the rubber to dry out and crack, increasing the risk of a blowout.

Contamination: Dirt, metal shavings, and degraded fluid inside the hose can eat away at internal surfaces, weaken reinforcement layers, and cause internal blockages that lead to dangerous pressure buildups.

Improper Installation: Hoses that are twisted, stretched, bent too tightly, or overtightened at the fittings are far more likely to fail prematurely. Even something as simple as using the wrong bend radius can compromise performance.

Understanding these causes and how they show up in the field is key to catching problems early—and keeping your equipment running longer.

Warning Signs Before a Blowout

While a blowout may seem sudden, hydraulic hoses almost always show warning signs before they fail—if you know what to look for. Spotting these early indicators can help you avoid a messy, dangerous, and expensive failure.

Here are the most common red flags:

Cracks, Bulges, or Worn Spots on the Hose: Visual damage is often the first clue. Look for cracks in the outer layer, areas where the rubber is bulging, or spots where the outer cover has been worn away—especially near clamps or where the hose rubs against other components.

Exposed Wire Braid: If you can see the steel braid under the rubber, the hose is already compromised and should be replaced immediately. Continued use could lead to a high-pressure rupture.

Leaking at Fittings or Connections: A slow drip or oily residue near a fitting could indicate a loose connection or a seal starting to fail. Ignoring it could allow the leak to worsen or escalate into a blowout under pressure.

Sudden Drops in Pressure or Performance: If your machine starts acting sluggish or you notice a dip in hydraulic responsiveness, it may be due to an internal hose failure or blockage. This type of failure is harder to see but no less serious.

Hissing, Whistling, or Rubbing Noises: A high-pitched sound near a hose can indicate a pinhole leak—or air being pulled into the system. Rubbing sounds could mean the hose is scraping against the machine frame and wearing through.

Stiffness or Brittleness When Flexed: During inspection, gently flex the hose. If it feels unusually stiff, brittle, or even crunchy, it’s likely aged past its service life and at greater risk of failure.

Operators and rental technicians should make these inspections a routine part of daily equipment checks. Catching a $50 hose problem today can prevent a $5,000 repair tomorrow—not to mention the lost income while a machine is out of service.

Prevention Strategies for Contractors and Rental Fleets

Preventing hydraulic line blowouts doesn’t require expensive tools or complex procedures—it just takes consistency, a sharp eye, and the right parts. Whether you’re running your own machine or managing a fleet, adopting a few simple habits can make all the difference, giving you a sense of security and control.

1. Perform Daily Walkaround Inspections

Start and end each day with a quick hose check. This simple yet crucial step can help you spot signs of wear, leaks, or rubbing before they escalate into a blowout. Pay close attention to spots where hoses bend or pass through tight spaces.

2. Replace Aged Hoses—Even if They Look Fine

Hoses degrade from the inside out. If a hose has been in service for years or exposed to harsh environments, it’s better to replace it proactively than wait for it to fail.

3. Use Correct Routing and Support

Improper routing leads to twisting, kinking, and rubbing—all of which shorten hose life. Use clamps, grommets, or protective sleeves to prevent contact with sharp edges or moving parts.

4. Select the Right Hose for the Job

Match the hose’s specifications (pressure rating, temperature tolerance, bend radius) to the application. Underrated or over-flexed hoses are much more likely to fail.

5. Train Operators to Report Early Warning Signs

Your crew is your first line of defense. Teach operators what to watch for and encourage them to speak up when something seems off.

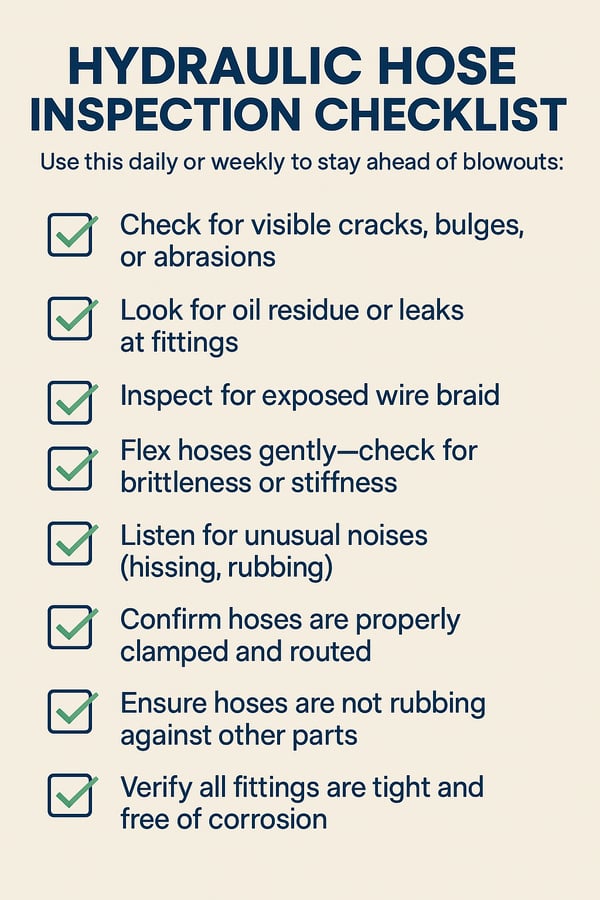

Hydraulic Hose Inspection Checklist

What to Do If a Blowout Happens

Even with the best maintenance practices, hydraulic hose blowouts can still occur—especially under demanding conditions. Knowing what to do in the moment can protect your equipment, your crew, and your bottom line.

- Shut Down the Machine Immediately: As soon as a blowout occurs, stop operating the equipment. Continuing to run a machine with a ruptured line can cause further damage to hydraulic components and spread contamination throughout the system.

- Depressurize the System Safely: Before inspecting or handling any hydraulic lines, relieve the pressure in the system. Pressurized fluid can still escape even after a blowout, posing a serious safety risk.

- Contain and Clean Up Spilled Fluid: Hydraulic fluid is hazardous to the environment and slippery on the jobsite. Use absorbent materials and follow proper disposal procedures. Rental businesses, in particular, should document and clean up spills quickly to maintain compliance and reputation.

- Identify and Tag the Failed Hose: Locate the point of failure and tag the hose for replacement. If you’re part of a team, this helps technicians or mechanics locate the problem faster and prevents accidental reuse.

- Replace With the Right Hose: Avoid the temptation to “make do” with whatever is available. Always replace the hose with one that matches the original specs for pressure rating, diameter, length, and temperature tolerance. Using the wrong hose could lead to another failure—faster.

- Inspect Surrounding Components: A blowout can be a symptom of deeper issues, such as a clogged filter, over-pressurized system, or misrouted hose. Take the time to inspect adjacent lines, fittings, and connection points before putting the machine back to work.

Conclusion

Hydraulic hose blowouts are more than just a mess—they’re a costly, dangerous interruption that most operators and rental fleets can’t afford. Fortunately, they’re also one of the most preventable failures on a machine. With regular inspections, proper routing, and timely replacement, you can identify and address problems before they escalate into costly downtime or damaged equipment.

If you’re ready to take a proactive approach to hydraulic system maintenance, Texas Final Drive is here to help. From replacement hoses and fittings to expert advice, we’re your partner in keeping compact equipment running strong.

Need help finding the right hydraulic pumps and final drives? Contact Texas Final Drive today for fast shipping and reliable support.