It's suddenly gotten pretty cold here in Texas where we are located, but we have customers from all of the country that have to deal with cold weather issues at temperatures far lower than what we ever get. In this Shop Talk Blog post, we are going to take a look at how to keep your equipment running in genuinely cold weather.

Here are a few other posts you might find useful:

Check the Tires

If you have a machine with tires, keep track of the inflation levels. Dropping temperatures can translate into a drop in tire pressure, which can lead to excessive wear. Check those inflation levels daily and you can reduce the risk of blowouts and uneven wear. If additional air is needed, inflate the tires in a warm environment. Experts recommend the use of dry nitrogen instead of air to inflate your tires.

Take Care of the Batteries

Tires and engines aren't the only components severely affected by cold weather: your batteries are, too. When temperatures drop drastically, your batteries are going to need almost twice the number of amps to to get the engine to turn over. Keep those batteries in storage at room temperature when those temps drop below freezing. And even if the temperatures aren't dropping below zero, keep those batteries charged up for maximum effectiveness.

Always Check Manufacturer Recommendations

Chances are that the manufacturer of your particular piece of equipment has recommendations for how to winterize it. Those recommendations can include cold weather fluids for things such as the crankcase and transmission, as well as hydraulic fluids and lubricants.

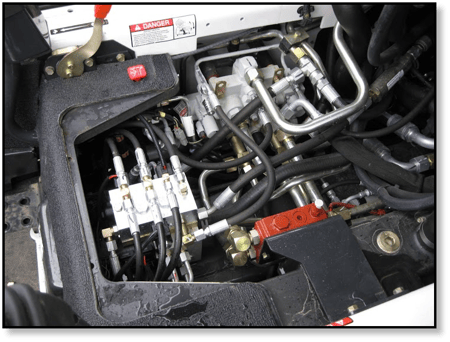

Check for Hydraulic Leaks

Cold temperatures can lead to stiffer hydraulic lines, which can more easily crack open or split. Seals can also harden, leading to similar problems. Leaking seals or hoses cause you to not only lose hydraulic fluid but can allow contaminants to access your hydraulic system.

Warm Up

Most manufacturers recommend that you give your equipment a chance to warm up before you put it to active use. In cold temperature, the viscosity of hydraulic oil and lubricants is going to rise which makes it harder to adequately protect the various components within your system. If you don't give these fluids a chance to warm up, you can damage your system and over time will see a reduction in productivity and efficiency.

In some instances, you may need to use a block heater to help your equipment's engine start in those icy cold temperatures. In addition, these block heaters can help warm up the hydraulic fluid.

Conclusion

Your equipment -- from compact skid steer loaders to massive hydraulic excavators -- needs some extra maintenance during the winter months when temperatures begin to drop. This can include checking the tires, keeping the batteries at room temp when not in use, allowing the machine to warm up before you use it, following manufacturer recommendations, and be extra mindful of potential leaks.