Swash Plates are a key part of the rotator group in axial piston hydraulic motors and pumps. Abrasive contamination can lead to premature wear of the swash plate (along with other critical components). In this Shop Talk Blog post, we are going to look at swash plates in more detail, including their purpose, potential issues, and how to extend their useful life.

Here are a few other Shop Talk Blog posts you might find helpful ...

- Bobcat 325 Rotator Group Damage

- Why Final Drive Bearings Fail

- 4 Key Maintenance Tasks for Final Drives

Rotator Group

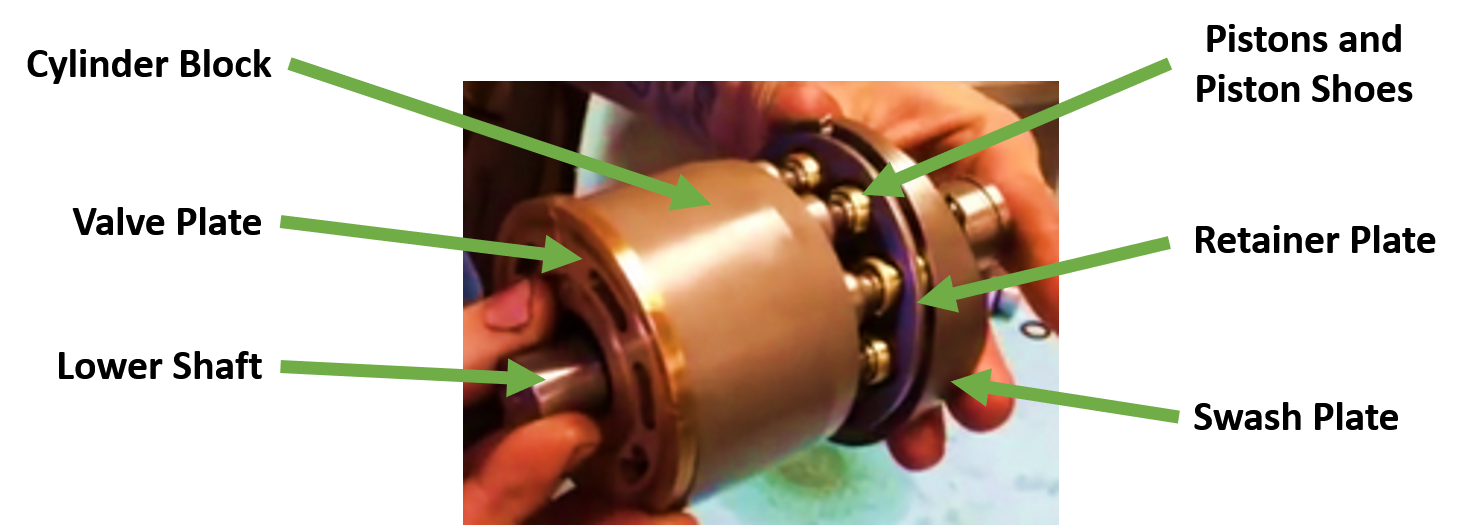

The swash plate is one of several components collectively referred to as the rotator group. In an axial piston final drive motor, the rotator group includes the cylinder block, valve plate, pistons, piston shoes, retainer plate, and the swash plate. You can see the different parts labeled in the image below.

Purpose of the Swash Plate

In a hydraulic motor, a swash plate aids in transforming the axial reciprocating motion of the axial pistons into rotary motion. Basically, the axial pistons move up and down, sliding along the angled surface of the swash plate. This causes the barrel to rotate,which in turn causes the drive shaft to rotate because the barrel is splined to the drive shaft. Note that the swash plate itself is stationary -- it does not turn.

Relationship Between the Swash plate and the Motor Displacement

The displacement of an axial piston motor is controlled by the angle of the swash plate: the greater the swash plate angle, the greater the displacement. Adjusting the swash plate angle allows the speed and torque of the final drive motor to be changed, also. This is the working principle behind a two-speed axial piston hydraulic motor. An actuator is necessary in order to change the angle of the swash plate, and usually takes the form of a servo-cylinder.

Potential Issues with Swash Plates

The most common mode of failure associated with swash plates is abrasive wear. The piston shoes slide along the surface of the swash plate, with the hydraulic fluid preventing metal-to-metal contact between the shoes and the plate. However, any abrasive contaminants in the hydraulic fluid will result in scoring of the swash plate. Scoring leads to increased friction, which results in losses.

And chances are that if the swash plate is scored, other parts of the rotator group (shoes, pistons, barrel) are going to be scored and worn also. The combined effects of losses in all of these components will negatively impact the performance of your final drive motor.

Extending the Life of Your Swash Plates

If you want your swash plate to last as long as possible, they key lies in preventing contamination of the hydraulic fluid. Taking care to keep hydraulic fluid clean will help minimize the scoring and wear experienced by the swash plate, as well as the entire rotator group.

Conclusion

The swash plate is a key component in the rotator group of an axial piston motor group as it controls the motor displacement and is crucial to converting translational motion along the axis into rotational motion. Its premature failure is normally due to contaminated hydraulic fluid that casues scoring not only on the swash plate but other parts of the rotator group.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.