Here at Texas Final Drive, we work quite a bit with radial piston hydraulic motors and Geroler motors. These motors, like anything else mechanical, will eventually wear out. The most damaging wear affects the cam ring, and that’s the topic for this Shop Talk Blog post.

.png?width=600&name=Hydraulic%20Motor%20Cam%20Ring%20Wear%20(1).png)

Here are a few other Shop Talk Blog posts you might find helpful ...

- Cam Ring Failure in a Final Drive

- Abrasive Contamination and Final Drive Motors

- Preventing Hydraulic Contamination

Why Cam Rings Are Critical

Radial piston motors and Geroler motors are sometimes referred to as cam lobe hydraulic motors because one of the key components it the cam lobe ring. This part of the motor experiences a great deal of wear that affects its surface, which is usually hardened to better withstand that wear. In order to understand why most of the damage starts here, it's a good idea to understand what happens inside a cam lobe hydraulic motor.

What Happens in a Cam Lobe Hydraulic Motor

A rotary valve distributes hydraulic fluid at a high pressure to each cylinder in sequence. When that pressurized fluid reaches the cylinder, it pushes outward. That forces the piston rollers against the lobes of the cam ring. As the piston rollers push against the lobes, the cam ring turns. A great deal of pressure and force builds up at the mating surface between the cam ring lobes and the piston rollers, and that is where the most wear is experienced.

What Type of Wear Do Cam Rings Experience?

What Type of Wear Do Cam Rings Experience?

Cam lobe rings can experience different types of wear, including fatigue damage from normal use and damage that results from contamination of the hydraulic fluid.

Fatigue Damage

The most common cause of cam ring failure is due to fatigue, which is completely natural. Any moving part will eventually wear out over time, and cam rings are no exception.

With a cam ring, wear primarily occurs where the rollers contact the interior surface of the cam ring. Engineers refer to this as Hertzian contact stress, and the study of it can be traced back to 1881 and the work of Heinrich Hertz.

These stresses can be made much worse if the mating surface of the cam ring doesn’t have an extremely smooth finish. Machining chatter marks left on the surface of mating surface, for example, will make Hertzian contact forces much worse. That’s why it is important to have a professional perform any resurfacing (such as grinding, polishing, or machining) that needs to be done to a cam lobe.

Damage from Contamination

Abrasive contamination will also damage the surface of a cam ring and significantly speed up wear as they abrade or actually gouge the surfaces of both the ring and the cam lobes. This produces even more contamination, resulting in a devastating cycle of wear.

Radial piston hydraulic motors are very sensitive to contamination, and the type of damage just described will have a negative impact on the performance of the motor.

Moisture in the hydraulic fluid, which is also considered contamination, can cause any developing microscopic cracks in the surface to grow far more quickly. This occurs as a result of the hydrogen in the water reacting with the mating surface under high pressure. This reaction is called hydrogen embrittlement and causes the surfaces to behave in a much more brittle fashion, which is why the cracks start to grow so quickly.

Example of Extreme Cam Ring Damage

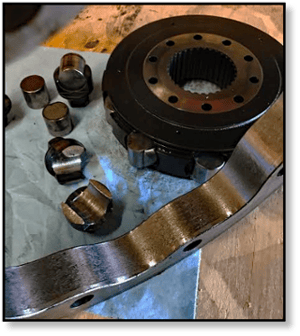

At Texas Final Drive, we had one Geroler hydraulic motor come in with some pretty severe damage. The piston rollers were extremely damaged, and some had even slipped out of place. This naturally resulted in severe damage to the cam ring. The mating surface of the cam ring was scarred up very badly. The overall damage was so bad that replacement was necessary. Fortunately, this level of damage is not the norm.

Conclusion

Radial piston motors will eventually wear out as a result of normal, everyday use -- but failure to keep the hydraulic fluid will speed up that process and can result in irreparable damage. These types of hydraulic motors are very sensitive to contamination, and if you notice a sudden reduction in motor performance then you might want to have a professional take a look at the motor.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.