In this Shop Talk Blog post, our goal is to cover the basic facts about case drain lines, case drain filters, and filter elements. Topics include what case drain filters are made from, how they are made, and whether you clean them rather than replace them.

Purpose of the Case Drain Line

All piston-type hydraulic motors are going to leak hydraulic oil from the rotator group. This is a good type of leak because it serves to lubricate the piston shoes, the swash or thrust plate, and the area between the cylinder block and the valve plate. This oil must then be returned to the hydraulic tank under minimal pressure -- that is the purpose of the case drain line. The case drain line will have an in-line case drain filter to prevent contaminants from traveling from the hydraulic motor to the hydraulic tank.

Case Drain Filter Assembly

The case drain filter assembly is contained within an aluminum canister that is about 1 ¼” in diameter and between 3” and 3 ½” long. When removing the filter, make sure to plug the drain lines to avoid losing hydraulic fluid or introducing contamination into the system.

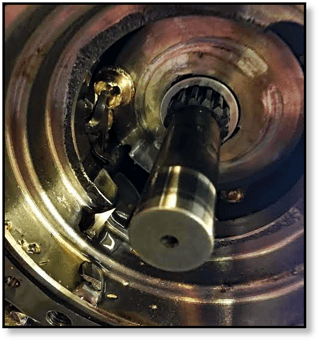

To access the filter element, simply unscrew the hex nut. The cylinder contains contains a tapered filter element, two seals, and a spring to hold the filter element in place. In the image, you can see a disassembled case drain filter assembly.

What Are Case Drain Filter Elements Made From?

For most machines, the case drain filter element is made of sintered bronze. Let that process for a moment: a filter made of solid metal?

While it may appear almost solid, it is actually made from thousands of tiny spheres of bronze that have been sintered together. The sintering process allows the filter to be porous enough for hydraulic fluid to flow through it, but dense enough to capture contaminants like metal flakes, tiny pieces of rubber, or metal shavings. Note that the sintered bronze gives a new, clean case drain filter a shiny, gold or bronze appearance.

How Are Case Drain Filter Elements Made?

The process used to create the sintered filter element involves powder metallurgy, where a spherical bronze alloy powder is compacted under extreme pressure into the desired shape and then heated, or sintered, until the spheres begin to fuse together. The sintering process is controlled to achieve the correct porosity for filtering. The result is a filter element strong enough to handle high pressures if needed, yet porous enough to allow for the free flow of hydraulic fluid through it.

Clean or Clogged?

If your case drain filter is no longer gold or bronze in color, then it’s time for it to be replaced. We recommend changing out your case drain filter any time you are changing out your other hydraulic filters or after you have experienced a final drive failure.

What Happens When a Case Drain Filter Gets Clogged?

When a case drain filter gets clogged, your travel motor will experience an extreme rise in pressure on the hydraulic side. This can lead to all kinds of problems...

When a case drain filter gets clogged, your travel motor will experience an extreme rise in pressure on the hydraulic side. This can lead to all kinds of problems...

- Blowing the piston shoes out of the rotator group

- Blowing the seals, allowing fluid and lubrication to leak out and damaging contaminants to make their way inside

- Serious damage to the cam in radial piston motors as the pistons lift completely off the cam during an inlet cycle and then hammering it during their outlet cycle

- Catastrophically damaging the bearings

- Freewheeling of some types of hydraulic motors

- Cracking or blowing off the cover plate of the final drive

Can You Clean a Case Drain Filter?

Some people may try to clean their case drain filters. We don't recommend this at all! Keep in mind that even if you try wire brushing or sandblasting a case drain filter element, it will just smear the trapped solids into the pores. That means you really aren’t unclogging it -- in fact, you may be clogging it even more. We recommend just purchasing a new filter element when your old one gets dirty. A new case drain filter is cheap, at least when compared to a new final drive!

Conclusion

You would be surprised at how many hydraulic motors arrive out our shop that have been destroyed because of a neglected case drain filter. That’s why we dwell on the subject so much: checking your case drain filter on a regular basis can save you hundreds and thousands of dollars in repairs and replacements. It may cost us some business, but we just hate to see an otherwise good final drive be destroyed because of a clogged case drain filter. Don't neglect this key aspect of final drive maintenance.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.