Bearings, axles, and gears inside a hydraulic final drive motor can be seriously damaged by abrasive contaminants in the lubrication or hydraulic fluid. However, many people don’t realize that all final drives generate contaminants as part of their regular use. In this Shop Talk Blog post, we are going to discuss generated contamination in your final drive motor, as well as how to keep that contamination to a minimum.

Generated Contamination

In our blog posts, we have talked quite a bit about contamination and the negative impact it can have on the performance and longevity of your final drive. However, even if you implement extreme practices of cleanliness when it comes to your hydraulic equipment, contamination can still be an issue. Even normal, day-to-day use will introduce contamination into your final drive. This kind of contamination is called "generated contamination".

How Contamination is Generated

As gears, bearings, and other metal parts are used, metal dust and filings are being ground away from their surfaces as they interact with other components. Significant contamination is also generated during the break-in period of new parts and components. This is usually in the form of fine metal scrap that looks like metal dust. It also common in new machines or a components that have gone through a complete overhaul.

As a final drive begins to wear, problems can arise with older parts. A chip from the surface of a ball bearing or a sliver of metal from a gear tooth can cause serious cascading damage to other components in the system. The particles of metal may circulate through the oil in the gear hub and cause scoring, grinding, chipping, and scratching the accelerates the rate of wear in other parts. If the bearings are affected, parts may find themselves out of alignment, which would further exacerbate the wear and deterioration.

This type of particulate contamination is very hard, very abrasive, and very bad for your system. It will most certainly will result in something wrong with your final drive.

Detecting Generated Contamination

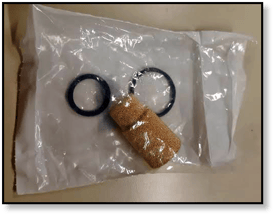

Generated contamination is why you will usually find a magnetic drain plug on your final drive gear hub. If the plug is magnetized, it will attract the steel particles generated during use and keep them from circulating through the system. It’s always a good idea to check the plug for excessive particles that could signal a major issue. This is the easiest way to detect this type of contamination in a final drive. It can also be detected by inspecting your hydraulic filters when replacing them.

We have encountered final drives that have been badly damaged by generated contamination. Here you can see brass shavings all over the inside of a final drive cover plate. By the time the damage has reached this level, your final drive may no longer be repairable.

How Generated Contamination can be Minimized

Generated contamination is unavoidable, but it can be minimized through the correct use of lubricants. Make sure that the lubricants (and in the case of a final drive, the gear oil) is the correct type for your machine and working conditions. Follow manufacturer recommendations for checking the lubricant levels and changing them out on a regular basis. This will enable the lubricant to better protect the key surfaces of components and help to flush out the harmful abrasive contaminants that may be generated.

For hydraulic systems in general, make sure to use the quality hydraulic filters that are recommended by the manufacturer of your machine. Cheap hydraulic filters can do more damage than good.

Conclusion

Abrasive particles generated during normal wear and gear is the number one cause of bearing wear and failure. Be vigilant about checking and changing your gear oil and using high quality filters on your system if you want to minimize the harmful effects of generated hydraulic contamination.

Here are a few more posts on the subject of contamination that you might be interested in ....

- Hydraulic Contamination Issues in Newer Machines

- Hydraulic Drive Motors and Contamination

- Types of Hydraulic Contamination that Affects Final Drives

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.