If you’re thinking ahead, you probably know that you need to be prepared for the zombie apocalypse. If you plan to build shelters and clean up zombie bodies, then you need to make sure your compact excavator is ready for the first outbreak and beyond.

Here are a few other Shop Talk Blog posts you might find of interest ...

- 4 Bad Habits that Mini-Excavator Owners and Operators Need to Quit

- Skid Steers and Zombies

- Hy-Dash Final Drive Autopsy

Craft a Reinforced Cage

First, you are going to want to make sure that you have the cab reinforced. The glass is probably going to break sooner or later, so you want a reinforced cage that the zombies can’t get their hands or teeth through. This can also be beneficial if they manage to flip your excavator over on its side, too.

Keep the Undercarriage Clean

Another important aspect of caring for your mini-excavator during the zombie apocalypse is keeping the undercarriage clean. Dirt, mud, rocks, stones, concrete, cement, and zombie parts will begin to build up. If left alone long enough, it can damage your tracks and even your final drive motor. It can also mess with the track tension and cause excessive wear on the rollers and idlers. Even if you can’t access a pressure hose, you can use a shovel and broom to get quite a bit cleared out every day. And remember that the longer you let the debris set and get packed in, the harder it is going to be to get it out.

Lay in a Good Supply of Gear Oil

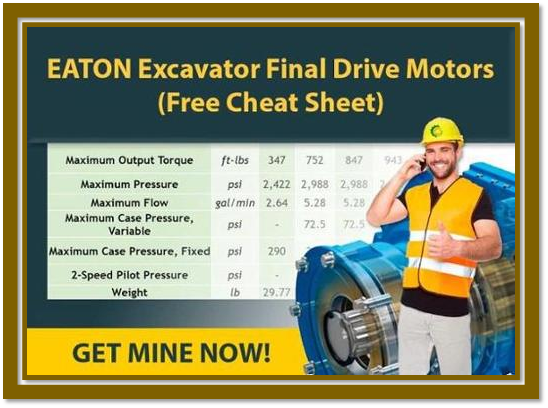

Lay in a supply of good gear oil for your final drive motors. After a while, you’ll probably need to scavenge it where you can, but remember that the gear oil is essential to keep that final drive running smoothly and transmitting the torque you need to plow through those zombie hordes.

You need to check the gear oil levels every 100 working hours and change it out at least once a year. And you’ll definitely want to scavenge some new hydraulic filters, too.

Clean Work Area

When you need to open up that hydraulic system for maintenance or repair, you need a clean work area without zombie innards, dust, dirt, or sand. If you can’t find a clean surface to disassemble hydraulic components on, find some clean cardboard or even plywood and lay it down. Any dirt, grease, or zombie juice that gets inside your hydraulic components (e.g., track motors, pumps, valve blocks) is going to cause damage, reduce the useful life of the parts, and compromise the productivity of your equipment. You want to avoid contaminating your hydraulic system!

Conclusion

Even if a zombie apocalypse isn’t impending, you should still keep your undercarriage clean, check and change your gear oil on a regular basis, and make sure that you only open up your hydraulic components on a clean surface.