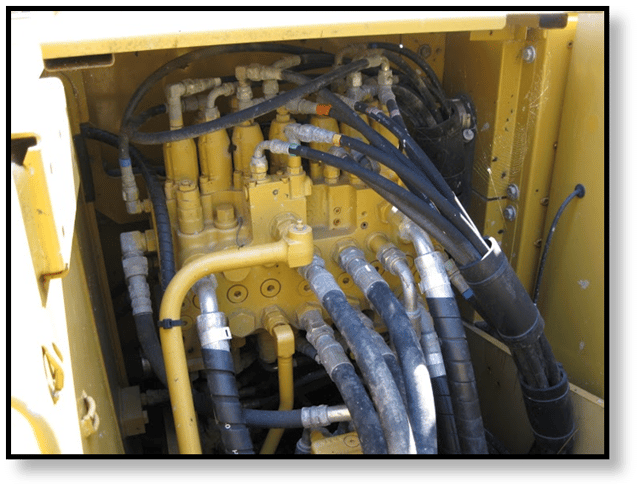

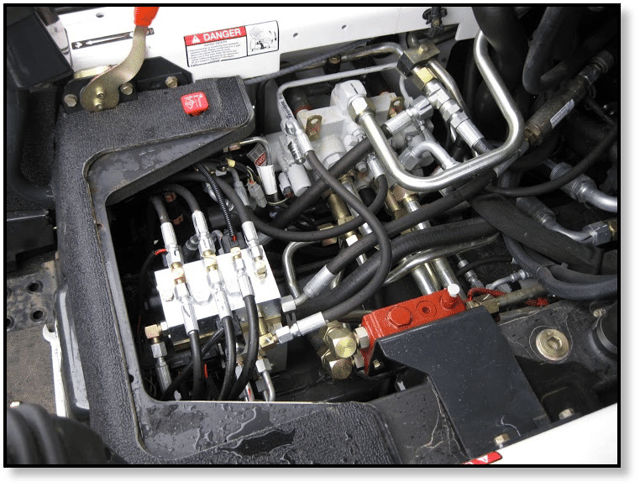

Hydraulic lines are a major part of any hydraulic system; the hydraulics on construction equipment such as skid steers, compact track loaders, and excavators are no exception. Since hydraulics are so vital to your equipment, we wanted to dedicate a Shop Talk Blog post to this subject. Whether you are maintaining your own equipment or restoring an older machine, here are five things you want to avoid doing with your hydraulic lines.

Avoid Tight Bends

One of the major causes of failure for hydraulic lines occurs when they've been routed in a way that requires them to make tight bends. A bend in a hydraulic hose should be no less than 3x its inner diameter. It may require a little bit more hose length, but avoiding extreme bends and curves is still a wise practice. Tight bends can not only damage the hose but also increase friction in the line as the hydraulic fluid passes that bend. The tighter the bend, the greater the loss of pressure as fluid passes it.

Avoid Abrasion

Another common issue with hydraulic lines occurs when the hose rubs against either another hose or another part of the machine. When the machine is in operation, this movement can be caused by pressurized fluid beginning to flow through the hose or the general vibration in the machine. This type of abrasive rubbing weakens the hose and eventually leads to a leak and failure. How can you prevent this? See if you can reroute the hoses. If you can’t reroute the hoses, then invest in a protective guard or cover for the hoses involved.

Avoid Contamination

When detaching hoses from equipment, it is very important that you don’t expose them to contamination. Before you remove the hose, make sure you remember to clean the immediate area. Once the hose is removed, plug the ends with something clean (not a well-used rag, for example) and keep them plugged until you are ready to reattach them. Don’t drop the hoses onto the ground where they can be exposed to dirt and debris. If you see evidence that the inside of the hose is degrading and coming apart, you must replace it immediately or risk contamination to your hydraulic system as well as the imminent failure of the hose.

Avoid Ignoring Leaks

Having a leak anywhere in a hydraulic system will compromise the efficiency and performance of your machine. Hose leaks can be the result of failed connections as well as cuts, holes, nicks, or abrasion. If a leak starts, it needs to be addressed for two reasons: first, leaks are bad for system performance and efficiency; second, if fluid can leak out, that means debris and contamination can get in.

Avoid Exposure to Extreme Temperatures

Hoses should be routed away from areas of the machine that can reach high temperatures during operation. Extremely high temperatures will weaken the hoses and cause them to degrade prematurely. This will then cause the hose to fail and can even contaminate your hydraulic system. If you cannot route the line away from the problem area, invest in an insulating guard or sleeve for the line.

Conclusion

Hydraulic lines are an often neglected but vital part of your hydraulic system, whether you have a skid steer loader or a full-sized hydraulic excavator. Lines should be periodically inspected for the very things we’ve listed in this post: tight bends, abrasion, contamination, leaks, extreme temperatures. If you need to fix a final drive, then take that opportunity to inspect the hydraulic hoses, too. This type of preventative maintenance for your hoses will help your machine to perform at peak efficiency and reduce repair costs.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.