When shopping for a skid steer or compact track loader, you might have noticed that one of the options available is radial lift or vertical lift. In this Shop Talk Blog post, we are going to take a lightning-fast look at the differences between radial lift machines and vertical lift machines in order to determine which is best -- and we've even thrown in an infographic for good measure!

Here some additional blog posts you might find interesting ...

- 5 Signs That Your Skid Steer Loader Hydraulic Motors Need Service

- Anatomy of a Good Final Drive Maintenance Plan for CTLs and Mini-excavators

- CTLs, SSLs, and Compact Utility Tractors: Which is Best?

So What's the Difference?

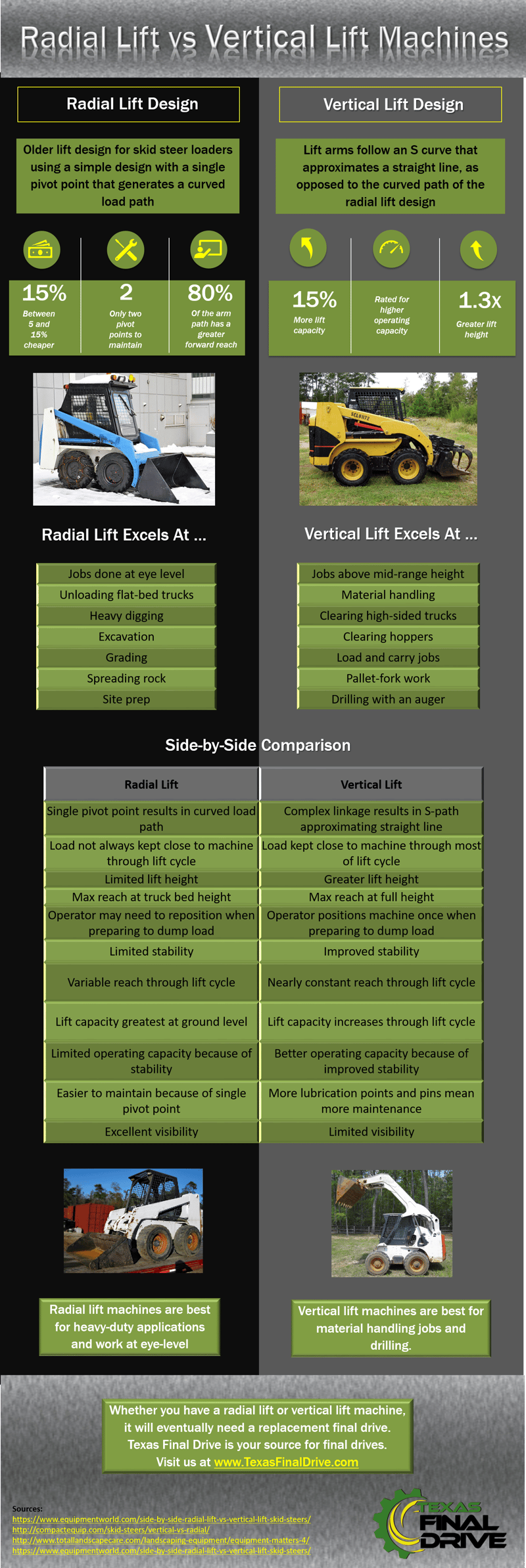

The difference between vertical lift and radial lift involves the path that the load takes as it is being lifted. This path is a direct result of the geometry of the skid steer (or compact track loader) arm. On a radial lift machine, the load follows a curved path. On a vertical lift machine, the load follows an S-shaped curve that almost looks like a straight line, as if the load was being lifted vertically. How a load is raised may not seem like a big deal, but the structural differences involved have a significant impact on what types of jobs a machine is best adapted to.

Radial Lift Machines

A radial lift skid steer loader or compact track loader has a simple and rugged arm geometry with a single pivot point for lifting.

Radial lift machines work well for jobs performed at or below eye level, and they perform very well in excavation projects that involve heavy digging. This machines also works well if you need to unload a flat-bed truck or do some site prep, including tasks such as grading or spreading rock.

Radial lift skid loaders and CTLs require less maintenance than vertical lift machines because they have fewer pivot points. They can also accomplish much more rugged jobs than an equivalent vertical lift machine. Radial lift machines tend to be cheaper, but will not have the same operating capacity because they are not quite as stable. However, they do offer better all-around visibility.

Vertical Lift Machines

Vertical lift SSLs and CTLs utilize a complex linkage mechanism to achieve vertical lift. They are well adapted to jobs above mid-range height and excel at material handling tasks, including pallet-fork work, load and carry jobs, and tasks that require clearing high-sided trucks.

Because of the vertical motion, these machines also excel at drilling jobs that use an auger attachment.

Vertical lift machines have better stability, greater lift height, and better operating capacity than radial lift machines. On the other hand, they involve more maintenance and cost 5-15% more than an equivalent radial lift machine.

Which Is Best?

Both vertical lift and radial lift machines have their pros and cons. Before purchasing one, establish what type of work you expect to use your SSL or CTL for before you settle on an option. In a nutshell, the vertical lift machines excel at material handling while the radial lift machines shine when it comes to heavy digging and earth moving.

Radial Lift vs Vertical Lift InfoGraphic

To help you better visualize and remember the differences between these two types of machines, we've put together an infographic for you. You can view it below or download your own PDF copy directly from this link right here.

Texas Final Drive is your partner in providing new or remanufactured final drive hydraulic motors from a single mini-excavator to a fleet of heavy equipment. Call today so we can find the right final drive or hydraulic component for you, or check out our online store to find your O.E.M. manufacturer brand motor now.